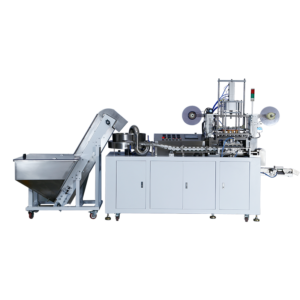

5 Gallon Cap Film Sealing Machine

The 5-Gallon Cap Sealing Film Applicator is specifically designed for sealing and applying anti-counterfeit film onto the surface of 3 to 5-gallon smart caps used for water bottles. This machine automates the process of adhering the anti-counterfeit film onto the smart cap surface, ensuring a secure seal and anti-counterfeit functionality that meets food safety standards. With high levels of automation, the machine provides excellent film application results. It is widely utilized by smart cap manufacturers, who produce 5-gallon caps for bottled water companies.

Main features of the 5-Gallon Cap Film Sealing Machine:

1.Equipped with automatic cap positioning, the system utilizes vacuum suction cups to transport 5-gallon caps to the automated film application component, ensuring precise and efficient placement.

2.Both the heating unit and temperature monitoring device feature automatic controls, enhancing product stability.

3.The equipment boasts a compact design and user-friendly operation, offering high levels of automation that significantly reduce labor requirements.

4.It can be tailored for production based on different cap designs as per user requirements.

5.It can be integrated into a complete 5-gallon cap production line alongside other injection molding, automatic cap padding, and automatic cap assembly machinery.

Video of 5 gallon bottle caps sealing machine:

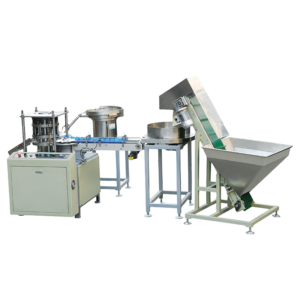

5-Gallon Cap Automatic Lining/Wadding Machine

The 5-Gallon Cap Automatic Lining/Wadding Machine is specifically designed for adding liner to 3 to 5-gallon water bottle caps. This machine automates the process of placing the sealing gasket inside the 5-gallon cap, enhancing its sealing performance and hygiene. The application of this machine not only allows 5-gallon cap manufacturing companies to save a significant amount of labor, but also ensures the production of caps that are more standardized and in line with food safety requirements.

Main features of the 5-Gallon Bottle Cap Lining Machine:

1.It features automatic cap orientation achieved through a combination of air conveyance and belt transportation, ultimately utilizing a chain conveyor with intervals to transfer caps to the gasketing position. This ensures smooth cap handling, accurate positioning, and low cap loss rate.

2.A precise pneumatic and electric-controlled robotic arm is employed to perform tasks such as picking, delivering, and applying gaskets. The gasket pickup is stable, the application process is hygienic, and energy consumption is minimized.

3.The machine is equipped with a gasket storage compartment, where operators need only place neatly arranged gaskets. Pneumatic devices are used to deliver gaskets uniformly.

4.The machine boasts a compact design and user-friendly operation, offering high levels of automation that significantly reduce labor costs for businesses.

5.All components of the machine that come into contact with 5-gallon caps and gaskets are made of stainless steel, fully complying with food safety production requirements.

6.The machine can be integrated into a complete 5-gallon cap automated production line alongside a 5-gallon cap injection molding machine, 5-gallon cap automatic assembly machine, 5-gallon cap sealing film applicator, and a conveying system.

Video of cap wadding machine for 5 gallon water bottle caps:

5-gallon cap inner plug inserting machine,cap assembly machine

Designed for 5-gallon water bottle caps, this machine automates the sorting and assembly of 5-gallon caps and inner seals, effectively addressing the issues of low production efficiency and contamination associated with manual assembly processes.

Main features of the 5-Gallon Cap Inner Plug Assembly Machine:

1.With exce llent logical design, machine can perform stable production.

llent logical design, machine can perform stable production.

2.Our fully automatic sorting system can sort out the shelf cap and inside plug. Hence the one step assembly can be completed.

3.The speed of down stream conveying system can be design according to injection system’s production rate.

4.Our machine assembly process can base on customer’s different cap design.

5.This machine can works inline with the liner machine in order to complete a liner smart cap assembly process.

6.This machine is controlled by PLC, inverter and full automatic design.